Press

Our current press releases, user reports, specialist articles and interviews are here for you to peruse.

Laser automation increases productivity by 40%

Automation and productivity are firmly linked for Dutch contract manufacturer Suplacon. With an automated storage and handling solution from Remmert, the family-owned company has been able to increase the output of two Trumpf lasers by 40%.

Long goods storage saves 30,000 litres of diesel per year

PBS Pulverbeschichtung Schreiner is a pioneer in production-integrated environmental protection and proves that efficiency and sustainability are not contradictory priorities. With a new honeycomb warehouse solution from Remmert, the service provider has improved its carbon footprint by a further 500 tonnes of CO2 per year and quadrupled its consignment warehouse capacities along the way.

Automation must adapt

For automation to pay off, it is necessary to integrate it into the existing manufacturing structure. This requires flexible solutions. This is exactly what the experts at Remmert specialize in and offer manufacturer-independent solutions that can be individually configured and used.

More efficient production through modern machines

Inefficient use of space in a metal processing plant leads to inefficient production. By using automated storage logistics, laser cutting machine productivity can increase by a large amount and operating space can be optimally utilized. A Wisconsin manufacturer is installing a Remmert vertical linear storage system to achieve this.

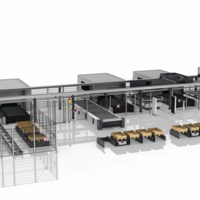

AGVs and robotics in sheet metal processing

The automatic loading and unloading of laser cutting systems is now part of the standard for modern sheet metal processing processes. With palletising robotics and automated guided vehicles (AGV), the next trends are now gaining ground in the plants.

Scarce resources in metal processing: how automation and time management can help

Labour, capital, space. These are the classic production inputs, known in business administration as resources. Metal processing, more specifically, requires: sheet metal, pipes, electricity, machines, skilled workers. And this is where the problem lies for almost all metalworking companies.

Driverless transport system complements automatic warehouses for XXL goods

When goods no longer fit on the standard pallet, Remmert's automatic storage, handling and transport systems are in demand.

Sheet metal storage tower extended with automation

Well begun is half done. This is a philosophy that helps Barbas Bellfires of Bladel in North Brabant in the production process. At its inception, the manufacturer of stoves and fireplaces produced everything through diligent effort. Metal plates were cut, bent, and welded by hand until an elegant stove or fireplace stood at the end of the production line. Things are different these days; a variety of automated solutions have now come into the picture. Remmert assumes responsibility for the beginning of the production process, so that Barbas Bellfires can work more efficiently and effectively.

How to optimize the flow of materials in four steps

Success factor process efficiency: More and more companies are recognizing the benefits of an automated flow of materials and therefore, are reorganizing their internal logistic processes. However, it can be noted that they often only consider individual stations of the material flow instead of the overall process – from the delivery of the raw materials to the shipment of their own products. The material handling expert Remmert provides the metalworking industry with information on how work cycles along the flow of goods can be optimized, to sustainably increase efficiency and productivity.

Remote services for proximity to customers in coronavirus times

Practice social distancing with Remmert services

Industry 4.0 in intralogistics: How state-of-the-art material handling works

Remmert gives new, innovative impetus for smart automation concepts in warehouses, the supply chain and co.

Optimized material flow in sheet metal processing

Remmert develops intralogistics at the Polish Instytut Mechaniki

Absolute process reliability through modern honeycomb storage system

Insect protection expert Lämmermann relies on the time- and space-saving honeycomb storage system from Remmert

Metalworking 2020: Targeting modularity and processing excellence

Remmert presents the decisive trends for a networked and integrated future in intralogistics

Cooperation between research and industry

Additive manufacturing revolutionises plant and mechanical engineering processes. An innovative approach helps industry manufacture cost-effective customised components and spare parts in small quantities.

Quickly, effectively and with a view to the future

Implementation of Remmert automation at Kamir Sp. z o.o.

Flexible modular principle for intralogistics concept

Siloanlagen Achberg GmbH & Co. KG (ACHBERG) relies on modular systems from Remmert when it comes to storage and provisioning of long bars and sheet metal

Tailored services - effectively prevent warehouse downtime

Remmert supports intralogistics customers with comprehensive support and personal contact

Receipe for success for intralogistics: Modularity and manufacturer independence

Remmert presents the future of sheet metal automation at the Blechexpo 2019

Progress in every detail: New concept for security and usability in the warehouse

Remmert supports Constellium in the modernisation of a long bar storage solution to make material flow

Modular concept for digital supply chain management

Remmert’s logistics software lays the foundations for greater efficiency in warehousing systems

Automation in a new dimension:

Horticulture and machine expert Nobels BV rely on a modular automation concept from Remmert

Event held to celebrate 25 years of employment: Remmert honors long-serving employees

Stefan Storck and Bernd Brinkmann were recently honored for 25 years of service at Friedrich Remmert GmbH during a celebratory event. Stefan Storck, head of electrical design, is responsible for the development of electrical hardware, while Bernd Brinkmann works as an electrician at the specialist in storage systems for long bars and sheet metal.

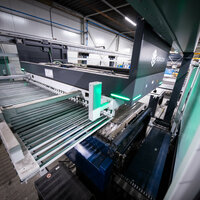

Productivity increase of 40 percent with automation by Remmert

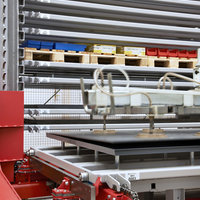

KÖNIG METALL has integrated an automation and storage solution by Remmert in order to meet the increasing customer requirements. On top, KÖNIG achieves an significant optimisation of the entire materials flow. KÖNIG METALL customers therefore benefit from shorter reaction times and increased flexibility in the supply of components and tools. The Remmert solution supports the production with a fully automated Remmert MIDI sheet metal store in combination with Remmert Laser FLEX 4.0. The loading and unloading of laser cutting systems works independently and without any personnel resources. The result is excellent: the specialist for pipe and sheet metal processing from Gaggenau achieves a 40 percent increase in productivity and space savings of more than 50 percent.

For the first time live at the Mazak booth: Remmert presents the LaserFLEX 4.0 at the EuroBLECH

The LaserFLEX 4.0 laser by Remmert GmbH celebrates its premiere at EuroBLECH: During EuroBLECH the operation of the handling aid is presented live at the Yamazaki Mazak Booth 132 in Hall 11. Connected to the Mazak Laser OPTIPLEX 3015 FIBER II 6.0 kW is the Industry-4.0 automation solution for the supply and removal of laser machines.

Blechexpo 2015

Remmert presents new handling solutions. Fully automatic laser feeding with Remmert Laser Laser FLEX 4.0. At the Blechexpo 2015, Remmert dedicates its efficiency guarantors in the production environment. At stand 1710 in hall 1, the company presents their new robot application Laser FLEX 4.0 - currently the fastest solution on the market for fully automated feeding of laser systems. Further highlights are the BASIC tower sheet metal and the Remmert sheet metal storage system. Both storage systems can be individually configurated and expanded using the connection with the Laser FLEX 4.0 to the fully automated sheet metal manufacturing unit.

Norsk Staal automated storage process

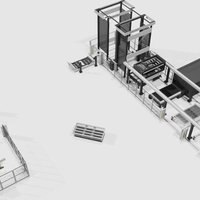

Maximum efficiency for long goods and sheet metal. Finally more capacity for adding value in storage and production. Norsk Staal, one of the leading steel and metal distributors in Norway, will soon be integrating a new automatic storage system from Friedrich Remmert GmbH. The system enables the company to combine the stocking of around 10,000 tonnes of long goods and 5,000 sheets of metal. The storage and material flow concept is designed so that it can simultaneously commission and adjust - without losing its efficiency.

New Remmert robot application for laser storage

LaserFLEX: The new robot application for sheet metal from Remmert GmbH is currently the fastest solution on the market for fully automated feeding of laser systems. Two automation units decouple the supply and removal for the processing machines. Material changing times of approx. one minute are the result. Users benefit from automated processes, manufacturer-independent integration and significantly reduced downtimes.

New Remmert BASIC tower for chimney manufacturer Interfocos

Simply well stored. Interfocos are increasing their manufacturing capacity and integrating an automatic storage system with it. The Remmert BASIC tower sheet metal slots perfectly into the location concept of the Dutch chimney manufacturer. Thanks to a compact design and powerful drive concept, the system enables quick access to the stored sheet metal and operating production. Interfocos thus maintains the short delivery times they are accustomed to and increases their turnover.

Ingrid L. Blecha Ges.m.b.H. is bringing balance to their warehouse

The Remmert honeycomb storage system is a real success factor. Individual requirements need individual solutions. This is especially apparent when implementing a sophisticated logistical project like at Ingrid L. Blecha Ges.m.b.H. The Austrian aluminium specialist commissioned Friedrich Remmert GmbH to optimise their storage strategy for long goods. It was a total success for Blecha. Today the company has a highly efficient storage and material flow concept. The centre point of it all is a powerful Remmert honeycomb storage system, which is custom-made to meet the central challenges of commissioning and sawing perfectly.

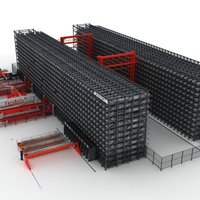

Remmert brushes the dust off the Sturm Group’s storage

Three advantages in one stroke. With their new, fully automated long goods storage system, the Sturm group is reducing their storage spaces by 70 percent despite increased capacities and improving the performance of the connected machines. The bridge storage system was custom made by Remmert precisely to Sturm’s requirements. Besides the optimisation of the flow of material and material handling, particular focus was given to efficient utilisation of the hall and site area space.

Fire brigade technology manufacturer integrates Remmert bridge storage system

A reduced storage floor space with increased productivity - these are the goals of Rosenbauer International AG. To reach these goals, the company is integrating a bridge storage system from Remmert over the next few months. A significant increase in the available space and an increase in machine use are just two of the advantages of the investment. With this storage system, Rosenbauer lays the foundation for its future growth.

Remmert sheet metal and long goods storage: Storage technology that grows

Successful industry companies adapt to changing market conditions in more and more flexible ways. In order to do this they need maximum flexibility in intra-company logistics and production. And by this we don’t just mean the usual compromise and inbetween solutions that lead to broken flows of material and inefficient processes in the long term. More and more companies are aiming for maximum flexibility, these are those that have applied growth technologies from the very beginning.

Remmert honeycomb storage system with LED lighting for Fischer Elektronik

1,500 m² hall space acquired. Currently perhaps the most unusual automatic high-rack warehouse in Germany is in Lüdenscheid: There Fischer Elektronik GmbH & Co. KG have built a 17 m high honeycomb storage system at their base on a slope. The storage system, which is used to store aluminium sections at a constant humidity, is illuminated with LED lights to display the structure in the Fischer colours or the brand colours of a business partner who is a guest on the visitor platform.

Fully automated sheet metal storage system and processing procedure

Efficiency up - costs down. Anyone who wants to reduce the storage floor space, material handling time and manpower in their sheet metal storage system by at least 50% should switch to fully integrated storage and manufacturing processes. This is the advice offered by sheet metal processing specialist Hase GmbH, after achieving precisely these results by installing an automatic sheet metal storage system from Friedrich Remmert GmbH.