Remmert News

Here you will find the most up to date news on Remmert and the newest sector trends.

Remmert keeps you up to date!

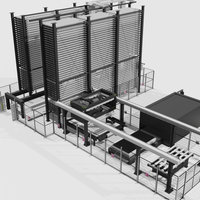

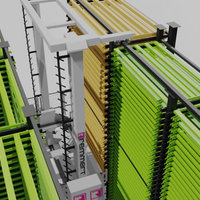

Automated picking warehouse for long goods with energy recovery

When large quantities of bars, tubes and profiles with a length of six meters and more need to be stored in a space-saving manner and picked quickly, Remmert's storage and handling solutions come into play. At Logimat 2024 in Stuttgart, Remmert will be presenting optimized honeycomb storage technology and sophisticated order picking solutions for automated storage and fast order picking specifically for the requirements of the window and door industry.

Remmert donates e-bikes for educational centre

The trainees at the Wittekindshof training centre in Bad Oeynhausen were delighted to receive four brand new e-mountain bikes for their sports and fitness programme. The bikes were donated by Remmert GmbH.

Remmert continues to grow in Poland

Warehouse logistics specialist Remmert has opened its first branch in Poland. The company is thus expanding its consulting and technical services for its Polish customers.

Remmert PartnerDays in Amsterdam

Together with sales partners from 13 countries, Remmert organized the PartnerDays 2023 from October 23 to 25. For the first time, Remmert did not invite to Löhne, but to the beautiful Amsterdam.

Remmert sheet metal storage tower with new low-priced model

With the Remmert BASIC Tower, sheet metal and other flat goods can be stored close to production in a very compact area. At Blechexpo in Stuttgart (07.-10.11.2023), Remmert will present a price-optimized starter model.

Remmert honored as a family-friendly company

The compatibility of family and career is firmly anchored in Remmert's corporate culture. Remmert has now been recognized as a family-friendly company for this.

Remmert running group takes home trophy

With an outside temperature of more than 30°C and bright sunshine, the Remmert running group came out on top as overall winners at the Hermes Charity Run on Sept. 10, 2023 in Löhne. In addition, Jens Homann ranked second in his age group and third in the overall men's standings.

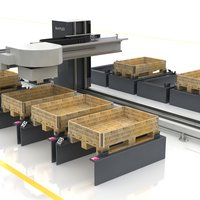

Palletising robotics reduce manual effort in laser cutting processes

With a tool change function and new software, Remmert will be presenting significant improvements to its robotics solution for the automatic sorting and palletising of laser-cut sheet metal parts at EuroBLECH 2022.

New variants for compact laser cutting centres with a high storage capacity

With the MIDI sheet metal storage system and the LaserFLEX automation for laser cutting machines, Remmert promises maximum utilisation of the available space for the storage and processing of sheet metal. This is made possible by new options for the transverse or longitudinal arrangement of the store and automation line to the laser cutting systems.

Hoekman Invests in 30 kW Laser from Eagle and Remmert Automation

In September 2022, one of the most powerful laser cutting centers in the Netherlands will begin operations. As part of the project, Hoekman Roestvaststaal BV, which specializes in stainless steel, has invested in a 30 kW Eagle laser cutting machine. To make best use of this high-speed machine, a Remmert warehousing and logistics solution with automated guided vehicles will ensure continuous flow of materials.

Ranga Yogeshwar congratulates Remmert on making it into the TOP 100

Überlingen - Honored at the German SME Summit: Ranga Yogeshwar pays tribute to Remmert GmbH on the occasion of its success in the TOP 100 innovation competition.

Sheet metal storage system supplies 4020 and 3015 Laser

SaMASZ Sp. z o.o., a leading manufacturer of agricultural and municipal machinery for pasture management, has chosen a new MIDI Combi sheet metal storage system from Remmert. This allows large quantities of sheet metal in 4020 and 3015 formats to be stored in a space-saving manner in a single, fully automated storage system.

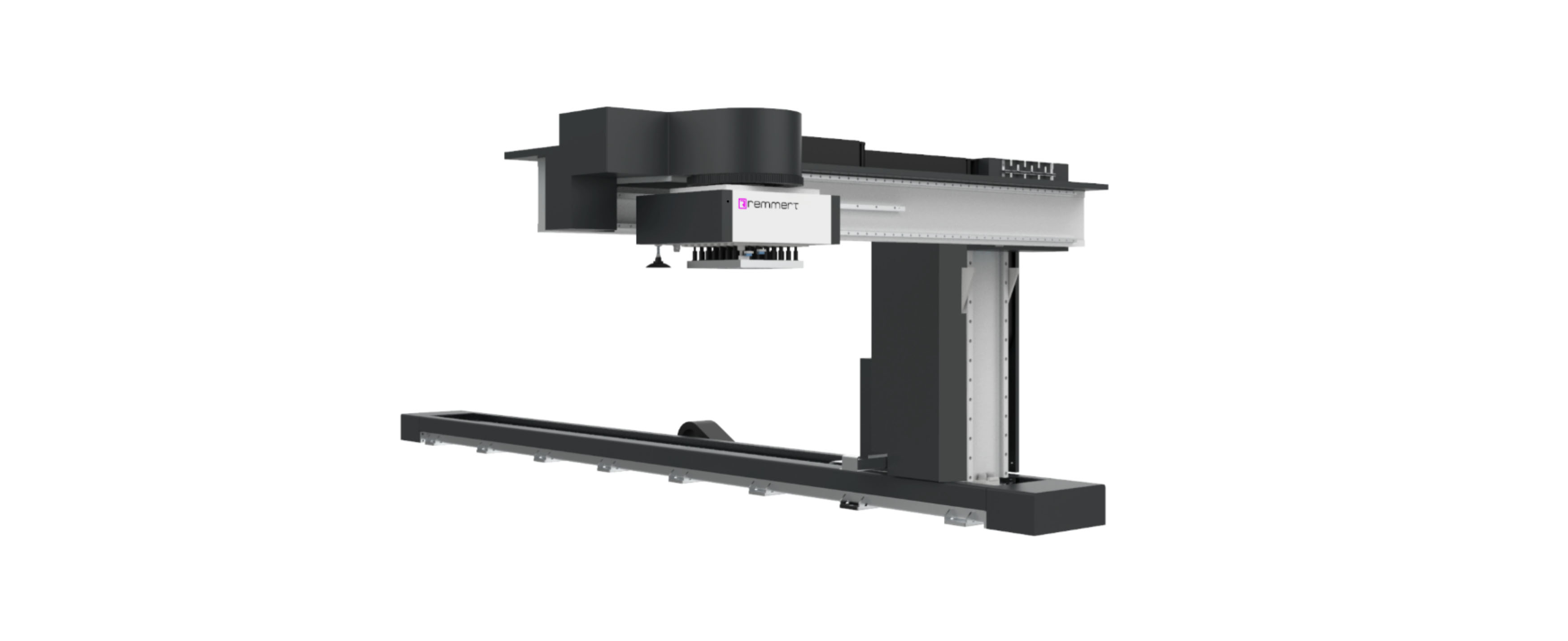

Remmert AGV has won the iF DESIGN AWARD 2022!

Löhne, May 2022 – Having won this year’s iF DESIGN AWARD, Remmert GmbH is among the prize winners of the globally renowned design label. The award went to the Remmert AGV – an automated guided vehicle system for heavy and bulky goods – in the Product discipline, Industry / Tools category. The iF DESIGN AWARD is presented once a year by the world’s oldest independent design institution – iF International Forum Design GmbH.

Remmert named top innovator

Remmert GmbH took part in the Top 100 competition for the first time and was immediately awarded as top innovator in its size class. For the innovative medium-sized company from Löhne in North Rhine-Westphalia, the award is further proof that it is on the right track with its company philosophy focused on continuous further development. On June 24, 2022, a personal tribute will be given by the science journalist Ranga Yogeshwar, the mentor of the Top 100 competition.

Remmert and KBM agree on strategic partnership

Remmert GmbH and KBM Automation AG have agreed on a strategic cooperation for sales and development of storage and automation solutions at Blechexpo 2021.

More laser cuts, less scrap: reusing metal sheet oddments efficiently and sustainably

How can residual sheet metal be efficiently reused after the laser cutting process? A new function of the Remmert handling system LaserFLEX makes it possible. Residual sheets are stored fully automatically back in the sheet metal storage system.

Important information to our customers

The Corona Virus has a firm grip on all of us. In this extraordinary situation, the protection of everyone's health has absolute priority - both our employees and yours. Therefore, we want to make a consistent effort to contribute to the containment of the virus.

Excellent employer: Remmert receives Top Job seal

The material handling expert Remmert has been awarded the seal "Top Job - Top Employer 2020".

DKSH brings Remmert’s material flow solutions to Asia

DKSH and Remmert have signed a distribution agreement covering its wide range of product portfolio for China, Malaysia, Taiwan and Thailand

Strategic cooperation agreement with WiCAM

At Blechexpo 2019, material flow expert Remmert and software manufacturer WiCAM seal a strategic cooperation agreement

From trainee to expert

Remmert offers specialised personnel ideal career development conditions. René Tiemann celebrates his 25th anniversary of working at the production site in Löhne, Germany. A quarter century of accumulated switch cabinet construction expertise: 1 August 1994 marked the start of René Tiemann’s professional career.

Strong family growth: New SortFLEX module complements tried and tested Remmert automation system

Fresh look for fully automatic sorting: The innovative “SortFLEX” module extends Remmert's FLEX family with order-specific sorting of laser-finished parts.

ITM 2019

Intralogistics expert Remmert provides a boost for sheet metal working

EuroBLECH 2018: Inspiring material flow concepts with modular and manufacturer- independent solutions

Material flow concepts that enhance productivity are in increasing de-mand among companies active in the sheet metal processing industry, Remmert GmbH can report after returning from EuroBLECH 2018. The intralogistics specialist’s portfolio of automation systems and consult-ing services for agile material flows garnered a great deal of interest at the event.

Laser cutting systems running at full capacity: Agile material flow concepts enhance productivity

State-of-the-art laser cutting systems combine high performance with incredible speed. Unfortunately, they spend far too much time not in use. What may sound like a paradox is actually a reality – and a costly one at that – in many production facilities. Companies looking to invest in a new laser cutting system often see it as a stand-alone solution. It is a situation that intralogistics specialist Remmert is all too familiar with. What these companies need is a consistent material flow and automation concept. That’s because the only way to achieve the return on investment they seek is by ensuring that the laser cutting system is in continuous operation. That is why Remmert advises companies that process sheet metal to consider establishing an efficient, future-proof material flow before they purchase such systems.

EuroBLECH 2018 Remmert shows the future of automation in sheet metal working

Remmert, the globally known company, is driven by improving agile material flow scenarios and implementing automation concepts for sheet metal working processes. At this year’s EuroBLECH, the automation and storage systems expert will be powered by its guiding principle “we make material flow”. In addition to leading concepts for material flow optimisation and increasing productivity, Remmert will also show proven solutions.

Remmert remains available during Christmas holidays

In preparation for the Christmas holidays we have organised a schedule of availability until the first week of the New Year.

Happy Birthday! Remmert celebrates 70th anniversary

2015 - we all have a reason to celebrate! In 1945, Friedrich Remmert founded the company known today as Friedrich Remmert GmbH in Löhne. Since then a lot has happened: Our family business has developed significantly with the market for long goods and sheet metal storage and has grown to have over 100 employees.

Remmert After Sales Service: refreshingly different

Sometimes it’s like being bewitched. Just when you need your storage system the most, everything comes to a standstill. But that’s OK if you have a service partner who knows the storage system and can find a solution quickly and efficiently. Lots of our customers can confirm this, they praise our After Sales Service.

The Remmert Laser FLEX has won hearts at the ITM in Poland

The ITM has been a complete success for us yet again. A highlight at our stand this year was the new Laser FLEX. Our robot application was presented to a specialist audience for the first time at the international trade fair. A successful debut for us - and a win for the visitors.

Remmert Laser FLEX - the fastest handling aid for sheet metal on the market

Supplying several lasers with material at the same time and fully automatically - with just one handling solution. Remmert Laser FLEX makes it possible. We have fitted our new robot application for sheet metal with two self-sufficient automation units. Users can take advantage of fully automatic manufacturing processes and material changing times of just 60 seconds.

Quicker, more flexible, more powerful: software modernisation by Remmert

From the old comes the new. A Retrofit is a quick and cost effective possibility to increase the efficiency of durable system. SCHMOLZ + BICKENBACH has recognised this. Thanks to the modernisation of the storage management system (LVS) PRO WMS Enterprise, steel retailers today have a modern system architecture again.

Storing and manufacturing in a future-proof way? Remmert knows how!

Flexibility in storage and production are indispensable nowadays. Finally customer requirements can’t always be predicted. For the Polish safe manufacturer Konsmetal, we a developed a future-proof storage system that can be flexibly adapted to the challenges of day to day business.

Remmert explains: Stocking long goods smartly

Storing pipes, rods and profiles in raw quantities. You can hardly imagine that was once the daily business for many companies in the long goods processing, manufacturing and distribution industry.

Remmert 2015 - ahead of the game internationally

If you rest you rust. We won’t let you get bored in 2015 - we’re taking to the international stage to be sure.