Completely automate laser cutting - this is how it works

The intralogistics processes involved in laser cutting systems hold great potential for increasing efficiency and saving resources. Remmert shows you what is possible.

There is still plenty of potential to increase efficiency through automation when it comes to the intralogistics processes involved in laser cutting systems. Remmert's sheet metal storage and handling systems allow to you use the full capacity of each individual laser cutting system while keeping personnel costs low.

Thanks to the modular design of Remmert's storage and automation solutions, they can be used flexibly in many situations and are suitable for the integration of all machine manufacturers. Subsequent extensions or changes of machine types are no problem whatsoever.

The FLEX modules for laser cutting systems at a glance

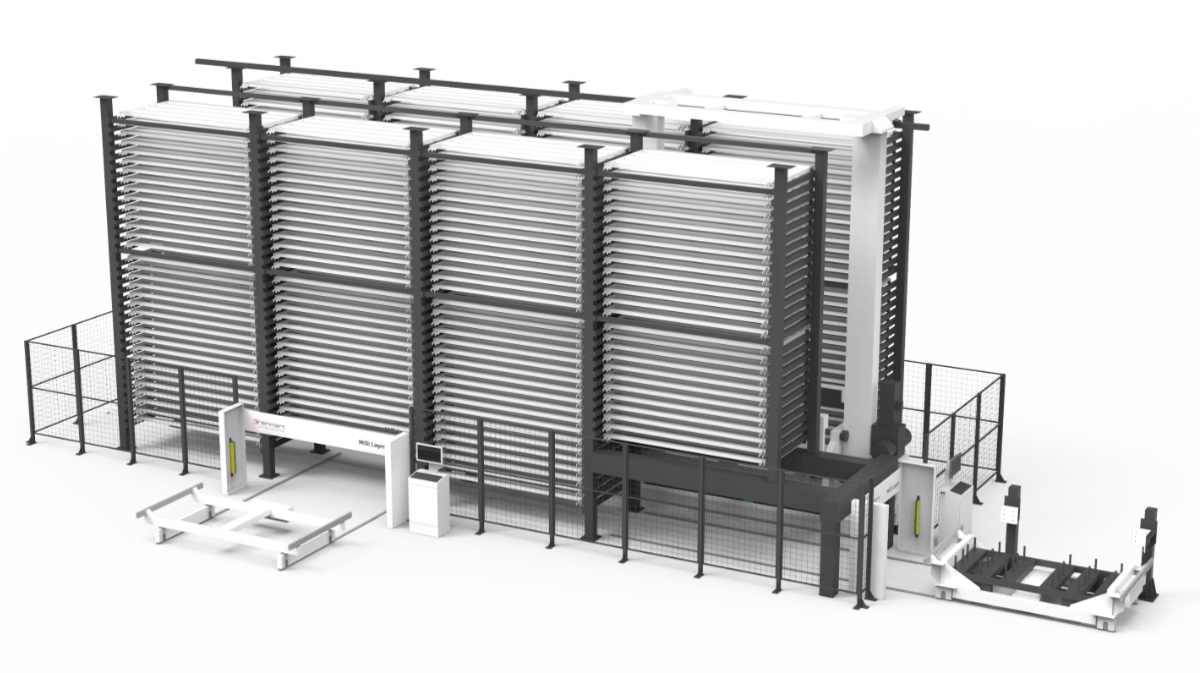

Storage systems for sheet metal

Automated rack storage with storage and retrieval machine (SRM) for sheet metal

- High capacity, can be expanded in a modular manner

- Stockpiling of raw sheet metal, residual sheets or as buffer storage for cut sheets

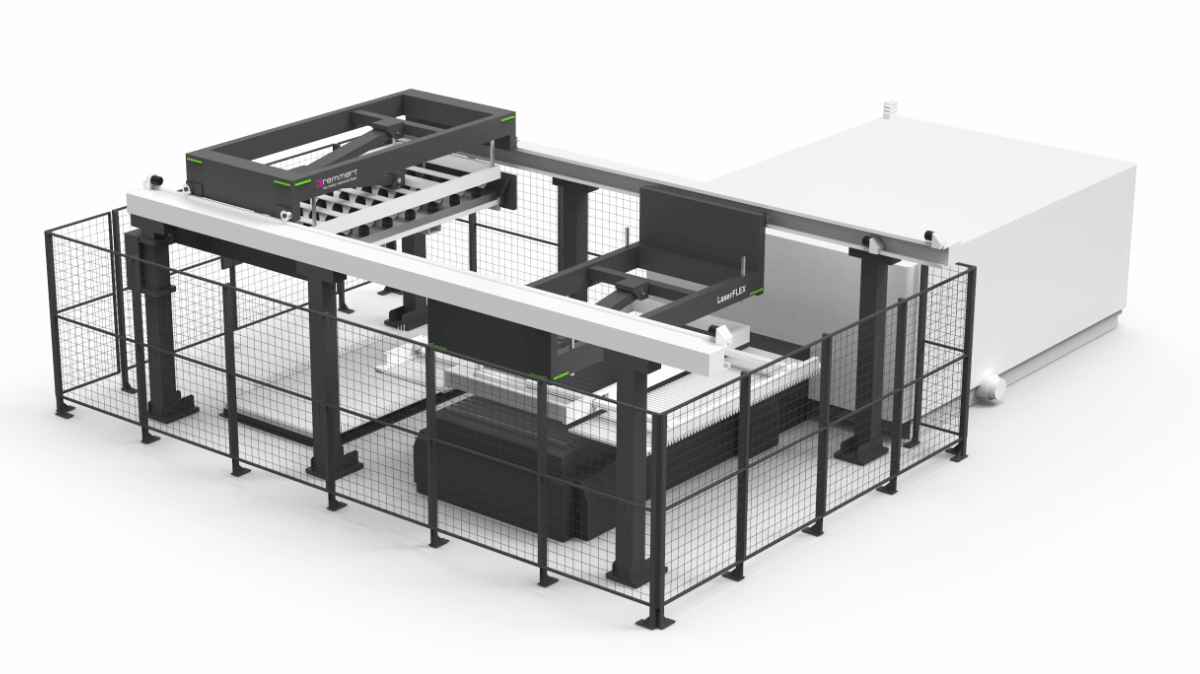

Gantry robot for loading & unloading

The fastest solution for fully automated loading and unloading of laser cutting machines

- Reduced processing machine downtimes

- Connection of several laser systems in chain formation

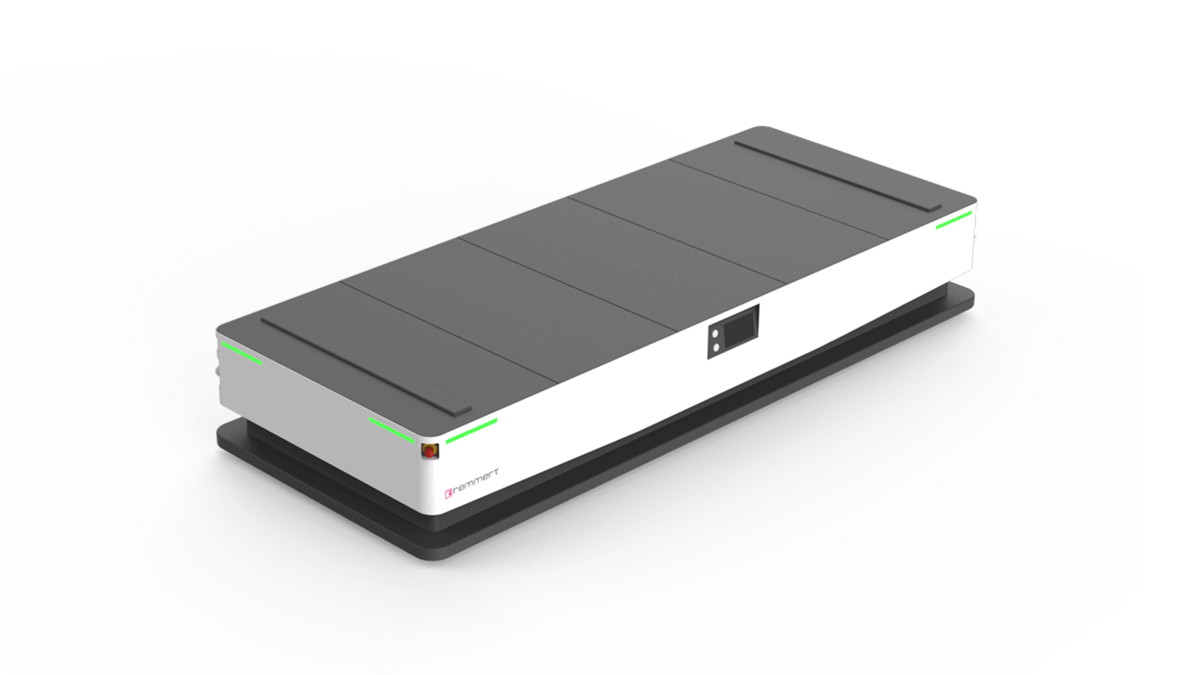

Automated guided vehicle system

Automated guided vehicle system for the autonomous transport of sheet metal

- Easy integration into existing structures

- Facilitates the spatial separation of storage and processing stations

Conveyor belt for sorting

Conveyor belt for manual sorting of laser-cut parts and sheet skeletons

- Selectable belt height for back-friendly posture

- Intuitive operation and therefore short familiarisation times

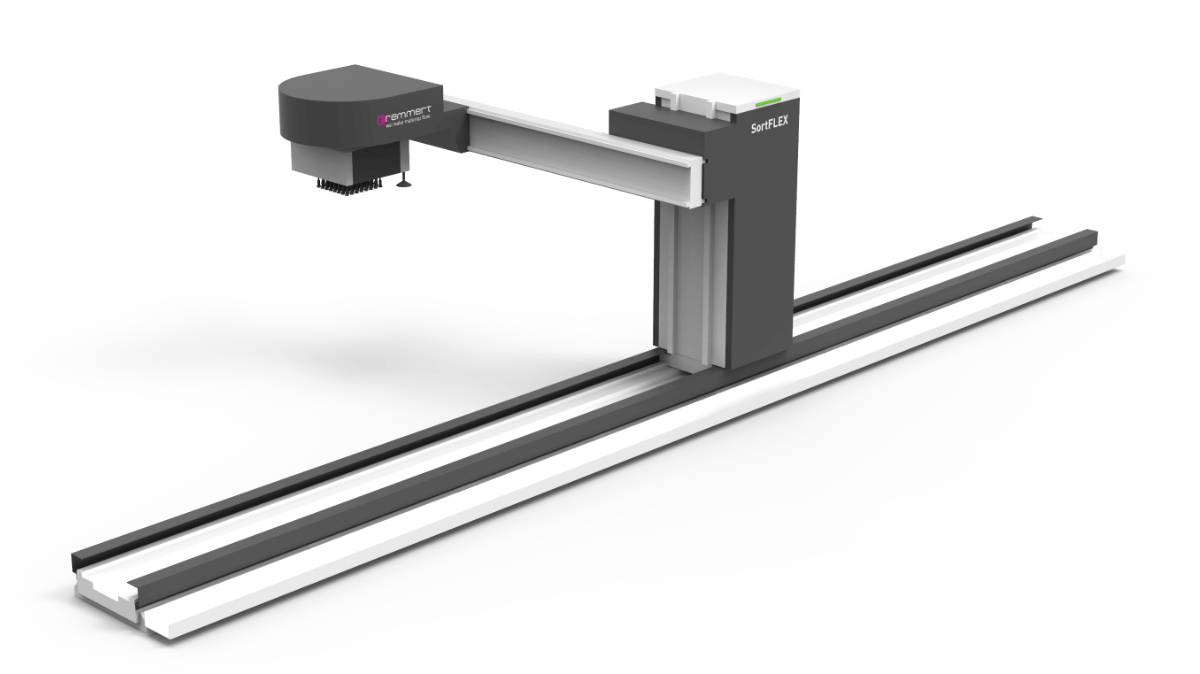

Robot for sorting

Sorting robot for fully automatic sorting of laser-cut parts

- Reduced personnel costs for sorting

- Increased productivity thanks to separate cutting and sorting lines

Monitoring & Control

![[Translate to english:] Remmert Steuerung mit WMS](/fileadmin/bilder/produkte/Logistiksoftware/Software_low.jpg)

Control software with integrated WMS and intuitive dashboard

- Warehouse management and control in one system

- Interface to processing machines from various manufacturers

References

Siloanlagen ACHBERG is a renowned developer and producer of plant components for the bulk materials industry - including containers and pipe systems made of stainless steel and aluminium that are used in the plastics industry. The construction of large plants with a lot of sheet metal and many pipes requires a lot of material. In the course of an expansion of its production facility, ACHBERG modernised its warehouse capacities with an emphasis on automated sub-processes. More...

Kamir sp. z o.o. has considerable expertise in laser cutting, bending, welding and turning. In 2017, the company initiated further initiatives to increase productivity in its sheet metal processing operations. With the purchase of two new laser systems, the aim was to implement the right automation solution to prevent potential downtime. Three key aspects had to be taken into account: achieving optimal process efficiency through simultaneous loading and unloading of the laser system, more efficient storage utilisation of approximately 80 pallets of sheet metal that needed to be stored and processed with minimal space requirements, and the possibility to future-proof the installed system and make it modularly expandable. More...

Nobels BV is the machine development and production site of Nobels Group, one of the world's most innovative suppliers of automation solutions for agriculture, horticulture and industry. In the course of the new construction and realignment of its production hall, the company decided to automate its laser systems with the help of Remmert's modular systems. The result: Nobels was able to more than double its output with one laser instead of two, and at the same time significantly optimise laser utilisation, thanks to an innovative, flexible retrieval strategy that was adapted to the production requirements. More...