The most important criterion for a storage system is flexibility. Besides lots of different long goods, lots of important work parts and tools for manufacture are also stocked in the systems today. To avoid any damage to the materials, for example, the storage spaces must be fitted perfectly to the long goods. If you’re bothered about the future, you’ll integrate a storage system into a modular construction. The advantage: It can be quickly and cost-effectively modified according to individual requirements. This is especially worth it when considering the dramatic developments in manufacture. Today, lots of companies are integrating machines with high processing speeds. To optimally support the handling process, the storage system must guarantee a high throughput, except for quick storage system movements, and also the time-efficient supply and removal of materials to and from the machines. The trend is towards storage systems with a direct connection to automation solutions to enable a manual shift operation when needed.

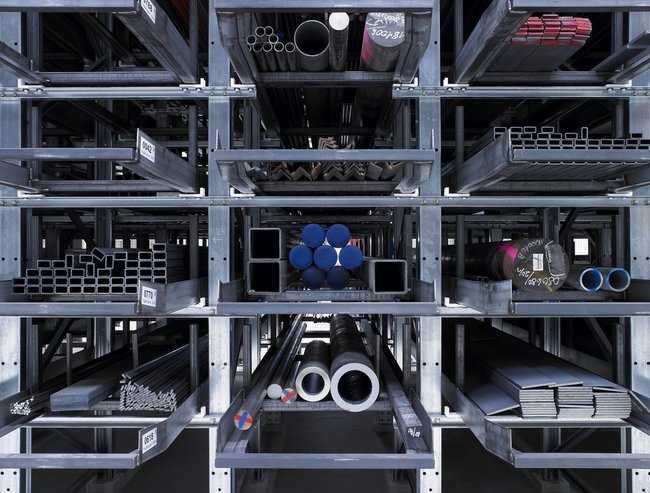

The requirements of a long goods storage system are unclear but you’re still looking for the right solution? Be inspired!