Users in the metalworking industry benefit from material flow concepts that are based on customer requirements and can grow with production challenges thanks to their modular design. The concepts therefore offer a high degree of flexibility and future-proofing. This solution complements the comprehensive and modular Remmert portfolio, which keeps a steady eye on material flows throughout the entire production. SortFLEX is currently being used in various pilot projects in special machine construction and will be introduced to the market in 2019. A particular advantage of the new Remmert module compared to competitive offers is that it doesn’t require tool changes during use.

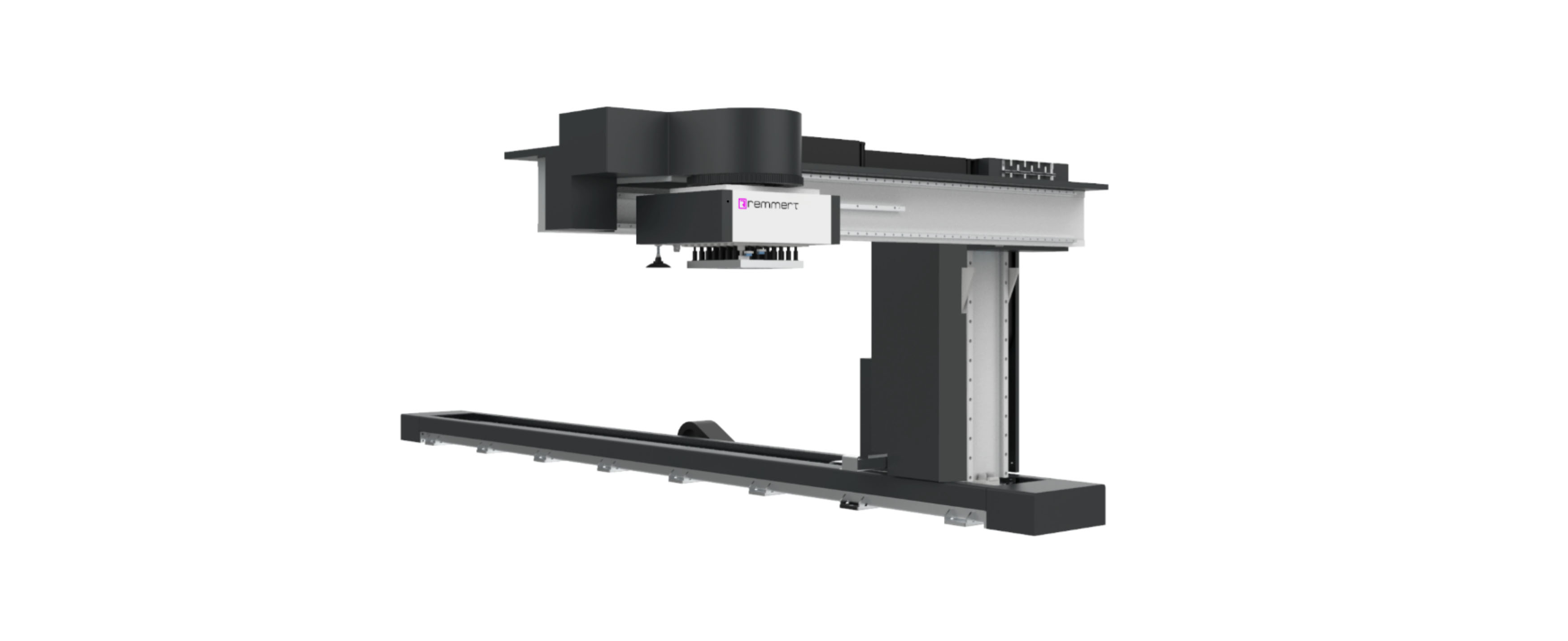

“Another special feature that distinguishes the FLEX family is that our automation modules can be used with any manufacturer’s devices, depending on the customer's request or production requirement. This enables every customer to use the most suitable laser for their production environment. In the last step, we ensure guaranteed smooth integration,” says Jan Schimmelpfennig, Product Manager at Remmert. “Modularity, adaptability and comprehensive efficiency are always our top priorities.”

According to the Cloud Automation Excellence study by Crisp Research, there is still a lot of catching up to do in terms of automation in the German industrial and automotive sector. Remmert's individually plannable automation concepts help users benefit from maximum flexibility for the future of their metal-processing production, measurable efficiency and productivity, and reliable investment security. SortFLEX integrates seamlessly with the tried and tested product family, which can easily grow with the user’s requirements. SortFLEX demonstrates its strengths particularly well in the FLEX family network, but can also be deployed individually and then expanded as required or integrated into existing processes.

“Future-oriented concepts for material flow automation and optimisation are the nuts and bolts of our innovative approaches. We always analyse the customer's initial situation and then implement a tailor-made automation concept that is consistent and can grow based on production requirements. Our flexible modules, powerful hardware and software paired with expert advice on an equal footing ensure that Remmert is the reliable partner for the future of sheet metal working. SortFLEX fits in with this perfectly,” concludes Schimmelpfennig.