Metalworking companies are increasingly complaining about staff shortages – even for simple tasks such as manual sorting and palletising of sheet metal parts after laser cutting. Automation of this monotonous activity can remedy this situation and, at the same time, further increase the overall equipment efficiency (OEE) of laser cutting centres in the long term. Remmert’s SortFLEX robotics solution is ideal for this purpose – and can even be used flexibly away from the shuttle tables of the laser machines.

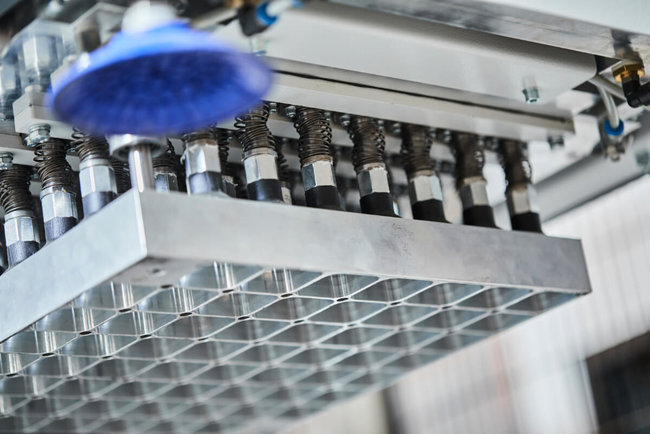

The 3-axis robot with cantilever arm is equipped as standard with a universal vacuum tool that can handle single sheet metal parts weighing up to 100 kg and up to 1000 x1000 mm. This already covers the majority of a typical parts spectrum. A new changeover function allows the use of further tools – such as magnetic heads for perforated sheets or suction spiders for larger parts.

Reduced work preparation and improved reliability

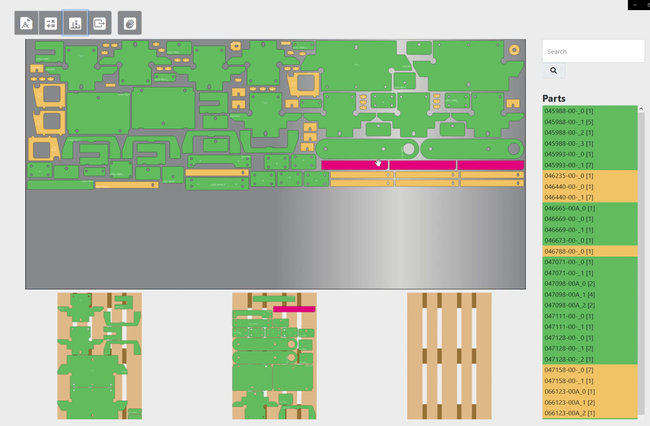

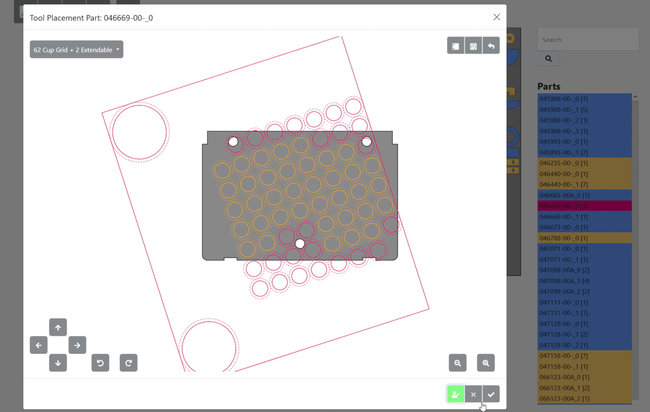

To significantly increase reliability in the sorting process and, at the same time, reduce work preparation, Remmert has also completely re-engineered the robot’s software. The new browser-based software first analyses the cutting plan and identifies all parts that can easily be picked up with the available tools. In this way, parts that require manual intervention can be identified from the outset. The placement of the tools on the parts and the deposition on the pallets are now also fully automated according to a geometric scoring model.

Remmert will demonstrate the SortFLEX application together with an automated guided vehicle (AGV) as an example of a decentralised sorting station at EuroBLECH (Hall 12, Stand D76).