With the new investment, the Polish-based company intends to largely automate its sheet metal working processes. Two laser cutting machines in the 4020 and 3015 formats will be fed directly from the warehouse via automation. A third laser has already been prepared as an extension.

The integration of the laser cutting machines and sorting automation into the sheet metal warehouse creates a space-saving and at the same time modern solution that enables Samasz to produce small batches efficiently, quickly, and with high quality. With the new sheet metal processing center, Samasz expects to gain noticeable competitive advantages in the manufacture of its products.

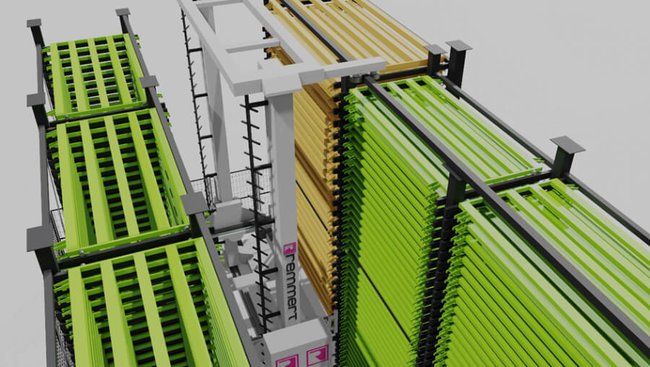

Sheet metal storage for 3015, 4020 and 6020 formats

The MIDI sheet metal storage system for 3015, 4020 or 6020 sheet formats ensures a high level of supply security and optimum utilization of the raw sheets thanks to its large storage capacity. Residual sheet metal can be automatically returned to storage and fed back to the laser cutting machines as required. The storage system can be designed with one or two rows and is modularly expandable for future capacity increases. With the MIDI Combi variant, Remmert offers a space-saving solution for the combined storage of 4020 and 3015 format sheets.