Highly volatile steel prices and sometimes extremely long delivery times are making the procurement of sheet metal increasingly difficult. In response, many metal processing companies are following the recommendation of crisis-proof stockpiling of raw sheet metal. However, this is accompanied by significantly higher demand for storage space. For this purpose, Remmert has added further options to its modular storage and automation system. This should significantly increase the degree of adaptation of the modular system.

Best use of space for maximum storage capacity

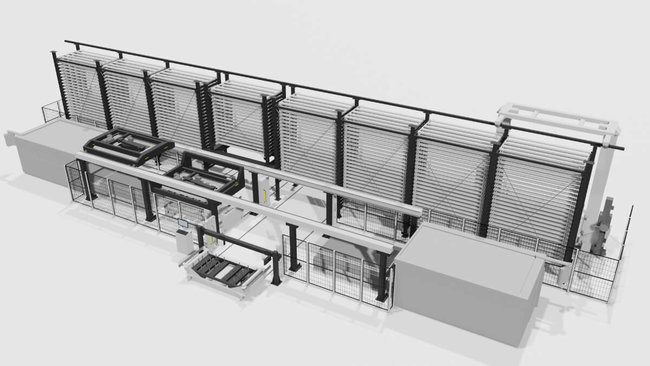

The single- or double-row MIDI storage system with up to 25 m storage height is designed for storing large quantities of sheet metal. The modular design allows very flexible adaptation to local conditions. This means that the storage locations for sheet metal formats up to 6020 can be arranged lengthwise or crosswise to the storage and retrieval system. This allows different arrangements to the connected laser cutting machine. A later extension by further racking blocks to increase the storage capacities is also possible without any problems.

Another new feature is the combination of 4020 and 3015 format storage locations in one system. Together with the LaserFLEX automation line, both 3015 and 4020 laser cutting machines can be connected to a store or automation line. With a predominant storage of 3015 sheets, the space requirement is reduced by 30% compared to a pure 4020 storage system.

Laser automation line parallel to the sheet metal store

With LaserFLEX Line, Remmert offers a new longitudinal variant of its successful laser automation solution – allowing laser cutting machines from different manufacturers to be automatically loaded and unloaded. The arrangement in a line with up to two laser cutting machines allows a very compact set-up parallel to the sheet metal store.

In combination with solutions for manual or automatic sorting as well as automatic residual sheet handling, users can realise maximally automated laser cutting centres with large storage capacities on a very compact footprint.