Family-owned Hoekman, based in Nieuwleusen, Netherlands, has specialized in the production of sheet metal parts and workpieces in stainless steel since the company was founded in 1986. Services offered cover the entire bandwidth of metal processing and engineering services. With a new laser cutting center including generous sheet metal storage, Hoekman wants to position itself even more broadly for job shop production of steel and stainless steel products. The core of the new facility will be Eagle’s currently most powerful “iNspire” laser cutting machine. With a 30 kW laser, the machine promises high speeds and low costs per workpiece.

Plate changing in under 90 seconds

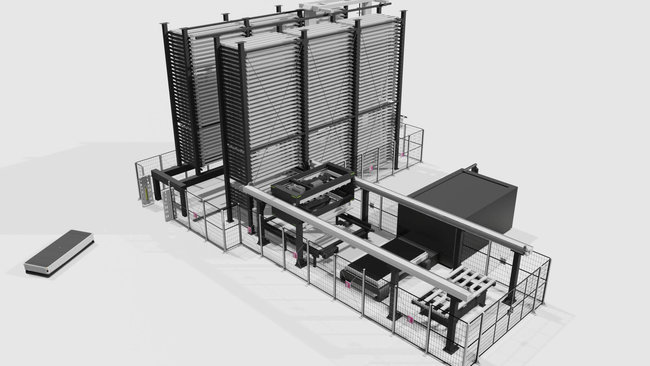

“Even the fastest laser cutting machine in the world is only as fast as the flow of materials before and after it,” says Jan Schwiertz, Remmert’s sales manager for the Benelux region. He and the decision-makers at Hoekman worked together on the logistics concept for the new laser center. Remmert is equipping the center with a storage and automation solution that will ensure the fully automated operation of the laser on a continuous basis. “We are using our LaserFLEX automation line with its two portal slides, which move on parallel levels above the shuttle table and thereby link the laser with the sheet metal storage system. While the lower slide is removing the cut sheet from the shuttle table, the upper slide can fetch the new sheet from the sheet metal storage system attached. This means we can achieve a change of plate in under 90 seconds, says Jan Schwiertz.

The automated warehouse, which features a storage and retrieval machine also supplied by Remmert, has a large storage capacity that will ensure a crisis-proof stocking of sheet metal. Leftover material can be returned automatically to storage.

AGV automates shuttling between laser and sorting

The sorting of the cut workpieces at Hoekman will be performed outside the laser center. Shuttling movements between the laser center and the sorting station will be automated with a driverless transport system (DTS). The Remmert DTS has been specially developed for the transportation of 3015 plate pallets. “Unlike when using forklifts for the shuttling, the DTS offers low personnel costs and three-shift operation. And since we can move omnidirectionally, that is, in all directions, the floor area required for maneuvering the large sheets and the paths are significantly less,” adds Schwiertz.