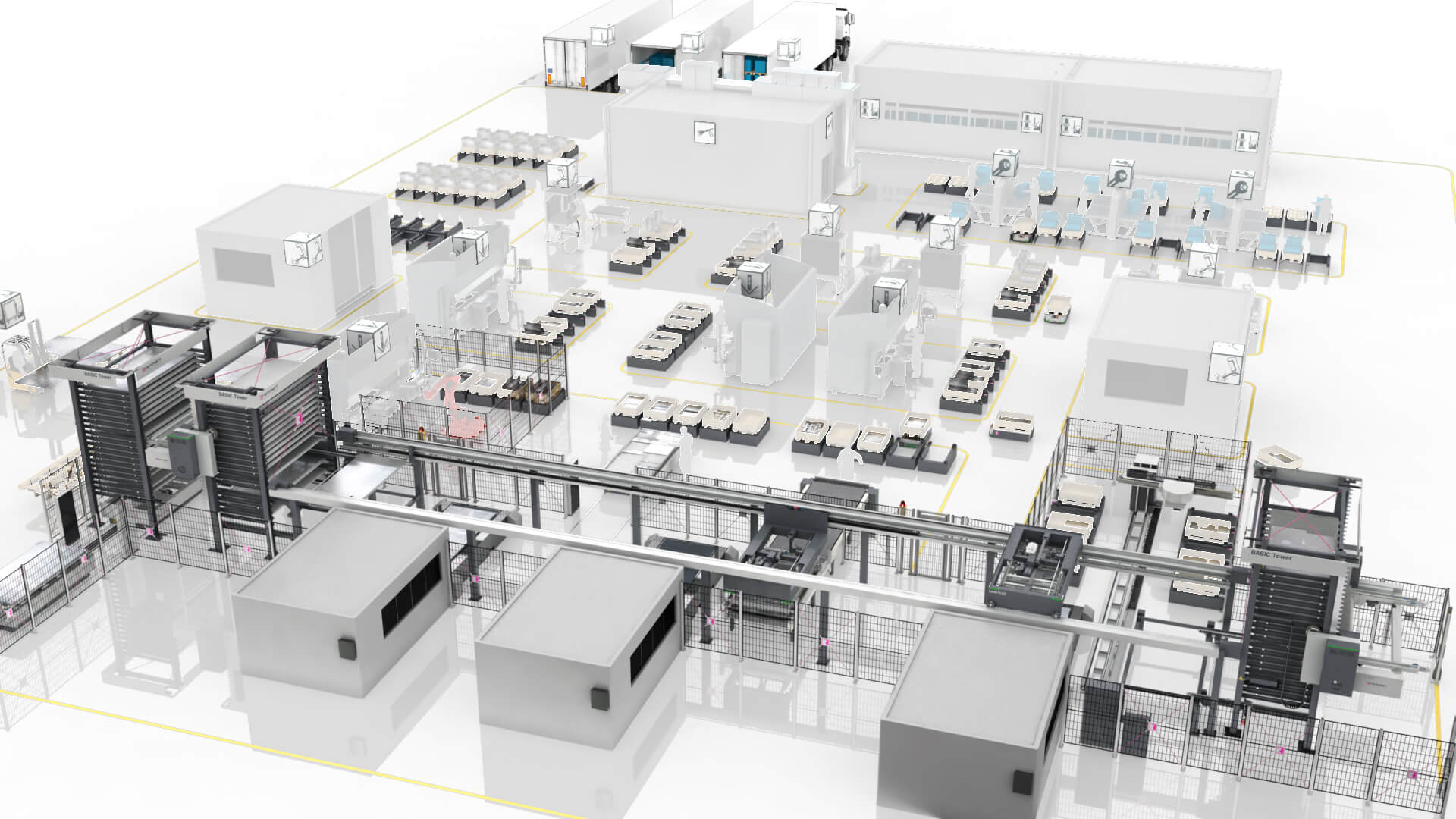

Remmert at the EuroBLECH 2022 Trade Show

Under the motto "Make it Max", Remmert will be showing at EuroBLECH in Hanover how you can optimally equip your sheet metal working processes for the future with maximum automated material flow solutions. Visit Remmert at the EuroBLECH!

Make it MAX - the Highlights from Remmert at EuroBLECH

Maximum overall equipment effectiveness (OEE)

There is still plenty of potential for increasing efficiency through automation in the intralogistics processes related to laser cutting systems. With Remmert's storage and handling systems for sheets in various formats and thicknesses, you can utilize the full capacity of each individual CNC cutting system while keeping personnel costs low.

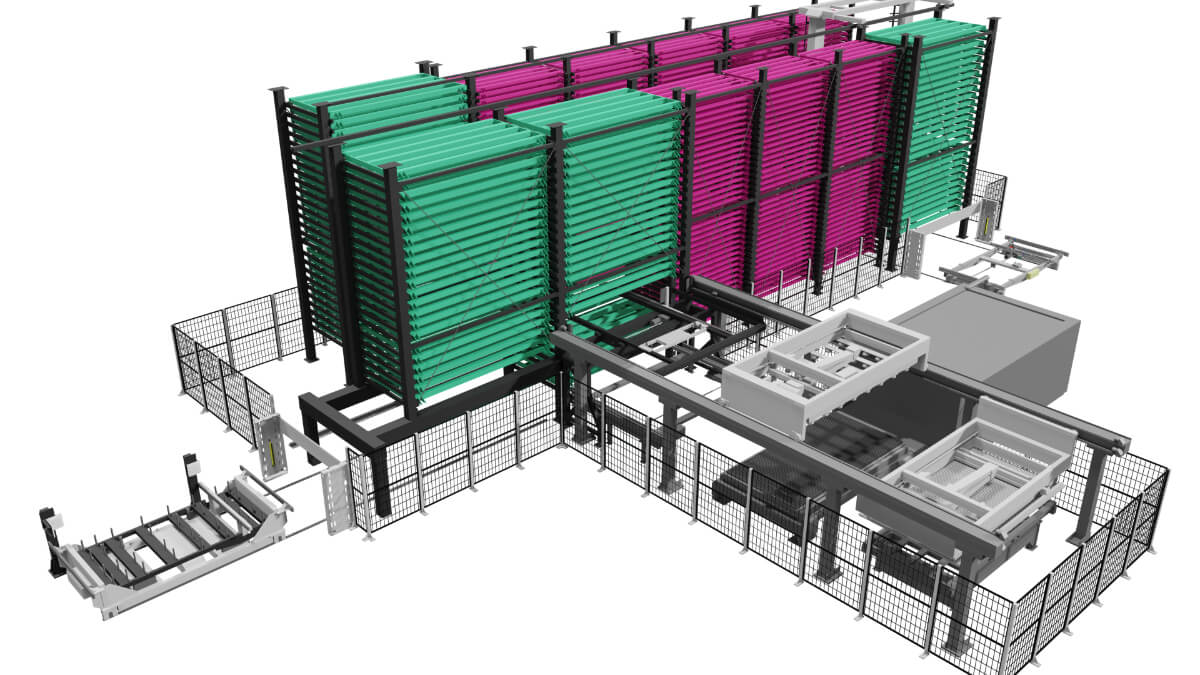

Maximum Security of Supply

The MIDI sheet metal storage system for sheet metal formats 3015, 4020 or 6020 ensures a high level of supply security and optimum utilization of the raw sheet metal thanks to its large storage capacity. Residual sheet metal can be automatically returned to storage and fed back to the laser cutting machines as required. The storage system can be designed with one or two rows and is modularly expandable for future capacity increases.

The MIDI-Combi variant with combined 3015 and 4020 storage columns is the space-saving intralogistics solution for fully automated laser centers with 4020 formats.

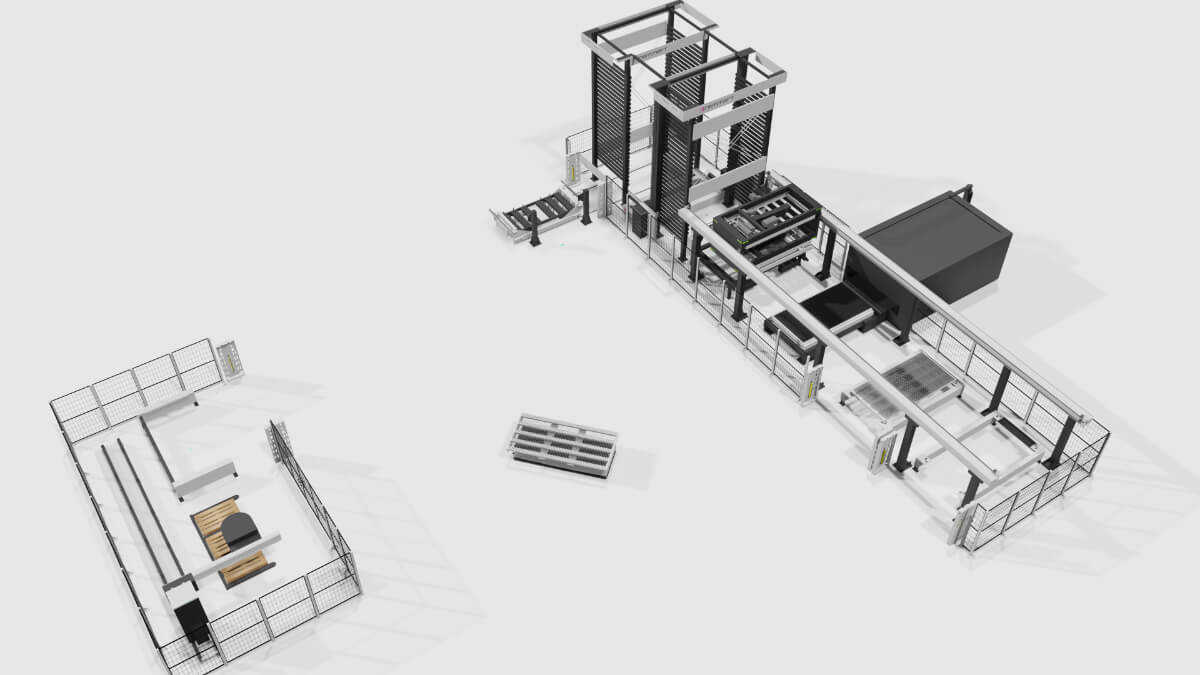

Maximum Freedom

With intralogistics solutions from Remmert, processes and capacities in sheet metal processing can be individually designed and easily expanded for future requirements. This is made possible by the modular design, which allows a high degree of adaptability and expandability with additional machines and automation modules. In this way, investment costs can be adapted to growing demand.

The Remmert AGV also creates unprecedented degrees of freedom in the spatial organization of sheet metal working processes.

Maximum Automation

The SortFLEX robotics reduces personnel costs in sheet metal processing through automated sorting and palletizing of laser-cut sheet metal parts. Deposit locations on pallets are also calculated automatically and in the best possible way according to space and order. SortFLEX can operate away from the laser's pallet changer or even be positioned stand-alone. This guarantees a continuous laser process without waiting time at the pallet changer. In addition, sheet blanks from several lasers can be sorted using one robotics.

See live at the Remmert booth in hall 12 the SortFLEX robotics in combination with the Remmert AGV!

And what can we do for you?

We’ll be happy to provide you with further assistance.