Storage of long goods in cassettes

Maximum storage volume and efficient picking operations for both long and bulky goods

Storage cassettes are an excellent way of storing long goods, for instance, piping, tubing, bars and metal profiles within easy reach, and without taking up too much space. Remmert automatic cassette storage systems enable a wide range of different items to be stored in very compact spaces. Automatic storage and retrieval machines and incoming and outgoing goods stations ensure fast, efficient and accident-free material handling with very few personnel required. The integrated WMS provides full control and transparency of all inventories.

The benefits of cassette storage systems for storing long goods

Cassette storage systems provide the benefits of safely storing many different goods in very compact spaces. Bars, piping, tubing, metal profiles, aluminium rails and other long goods can be stored in interchangeable cassettes, preventing them from falling out. Each cassette can accommodate different goods of varying lengths. Separation within the cassettes can be done via dividers. Small parts or pallets can also be stored in closed cassettes. Cassettes can be stored in the form of drawers within the shelving system. Remmert cassette shelving systems are equipped with automatic storage and retrieval machines. This minimises the amount of personnel and space required.

Remmert cassette storage types

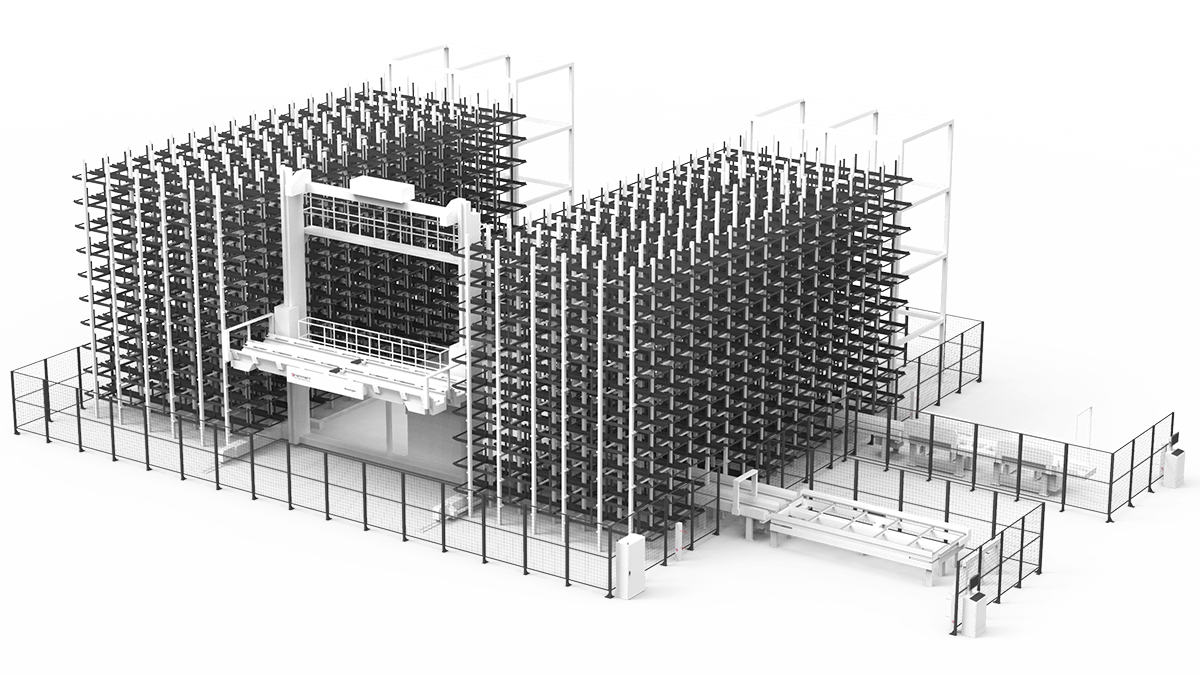

Honeycomb storage systems

Honeycomb-structured interchangeable cassette storage system with storage and retrieval machine at the front of the storage cassettes

- Maximum storage capacity for a wide range of products

- Very high access speeds for fast turnover of goods

Bridge storage systems

![[Translate to english:] Brückenlager - Langgutlager mit überfahrendem Regalbediengerät [Translate to english:] Langgutlager mit überfahrendem Regalbediengerät](/fileadmin/bilder/produkte/brueckenlager/Remmert_Bru__ckenlager_1200.png)

Long goods warehouse with overhead retrieval machine. Lengthwise access to the storage cassettes.

- High level of storage capacity with minimal space requirements

- Variable system design, easily expandable

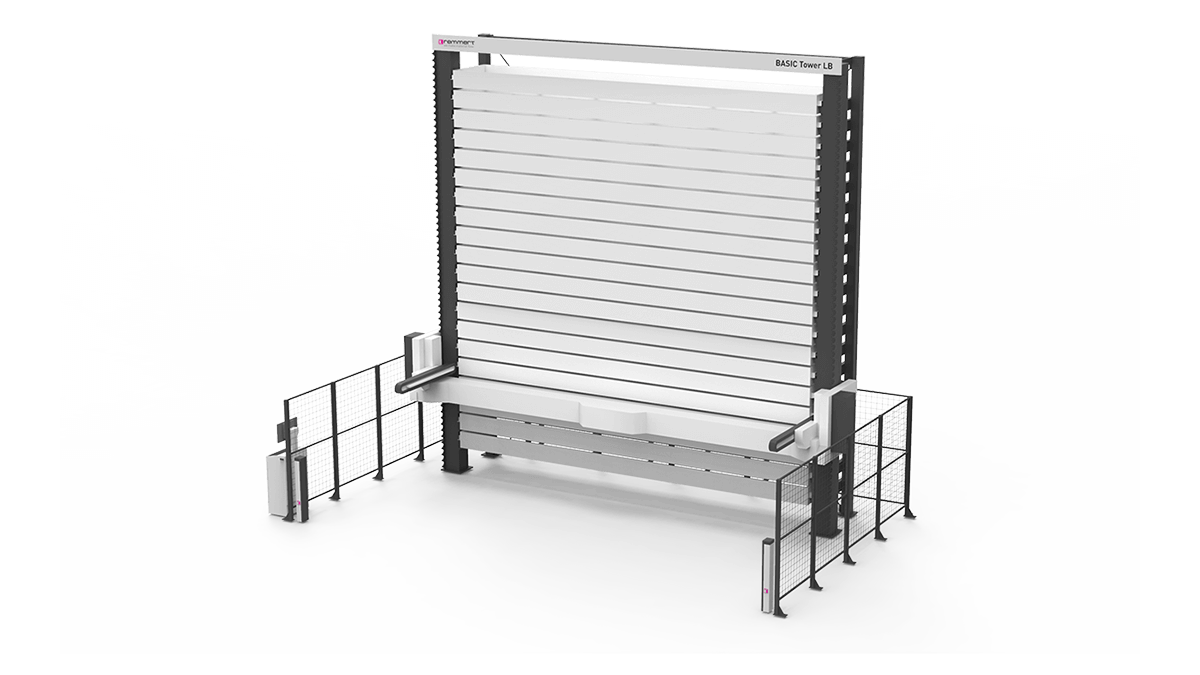

Tower storage systems

Automatic storage tower system with retrieval machine for lengthwise access and operation. Available also as double tower version.

- Storage of small quantities of long goods close to production

- Self-supporting cassettes with a wide variety of uses

Automation for Remmert cassette storage systems

In combination with robotics systems for Remmert material handling or automated guided vehicle systems, the long goods storage systems can be combined with sawing centres and other processing stations to form a fully-automated and complete solution.

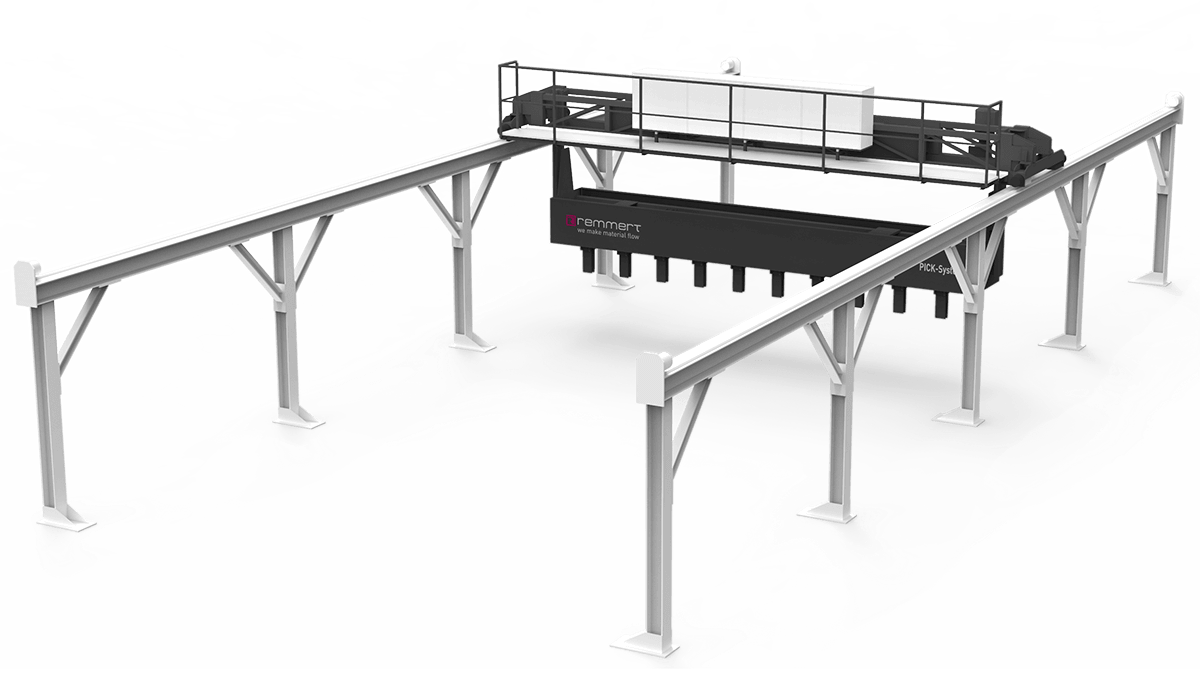

Gantry robots

Portal gripper for automatic removal of long goods

- Picking of up to 55 bars per hour

- Automatic operation of up to 4 sawing machines

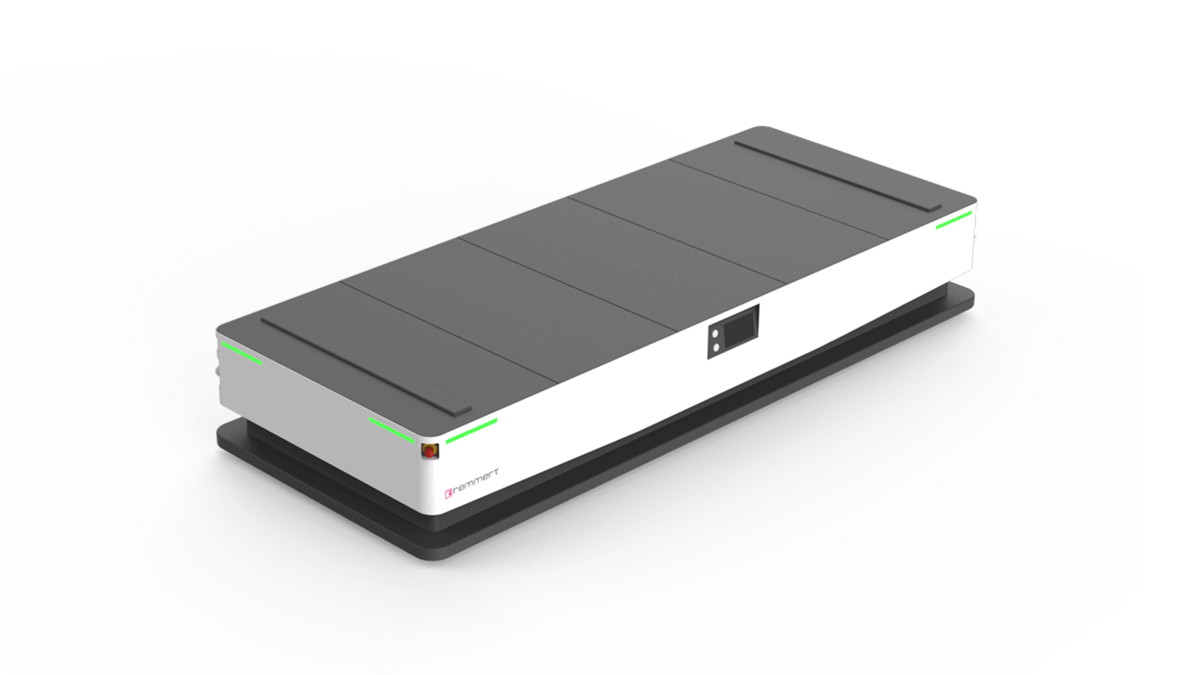

Automated guided vehicle

Omnidirectional AGV for heavy and bulky goods

- Transport payloads of up to 3 tonnes

- Optional scissor lift table to accommodate interchangeable cassettes

Logistics software

![[Translate to english:] Remmert Steuerung mit WMS](/fileadmin/bilder/produkte/Logistiksoftware/Software_low.jpg)

Control software with integrated WMS

- Warehouse management and control in one system

- Interface to processing machines from various manufacturers

References

Honeycomb storage and picking areas for aluminum profiles

PBS Pulverbeschichtung Schreiner is a pioneer in production-integrated environmental protection and proves that efficiency and sustainability are not a contradiction in terms. With a new honeycomb storage system from Remmert, the service provider is improving its carbon footprint by another 500 tons of CO2 per year and quadrupling its consignment warehouse capacities along the way. Read the complete success story...

Bridge Storage for Stainless Steel Pipes

Siloanlagen ACHBERG develops and produces silo plants for the bulk materials industry. ACHBERG's portfolio includes containers and pipe systems made of stainless steel and aluminum. The high demand for the processing of sheets and tubes has prompted ACHBERG to modernize its storage technology in the course of an expansion of its production facility. The company has focused in particular on automated sub-processes. Read the complete success story...

Fully automated sawing center for tubes and bars

SCHMOBI, one of the leading steel trading companies in Switzerland, has been operating a fully automated sawing center since 2006. Central elements are a storage and handling system from Remmert with direct connection to band and circular saws. In the course of a modernization, new sawing machines of the Amada brand were integrated into the plant. Read the complete success story...

Cassette storage for stainless steel profiles

Schlüter-Systems KG is the world's leading supplier of tile accessories. The company uses special storage cassettes for the in-house logistics of high-quality tile finishing rails. Two bridge storage systems and a high-bay warehouse from Remmert are central elements for reliable distribution logistics in the highly automated flow of goods. Read the complete success story here...