Laser Automation

Get the most out of your sheet metal cutting processes

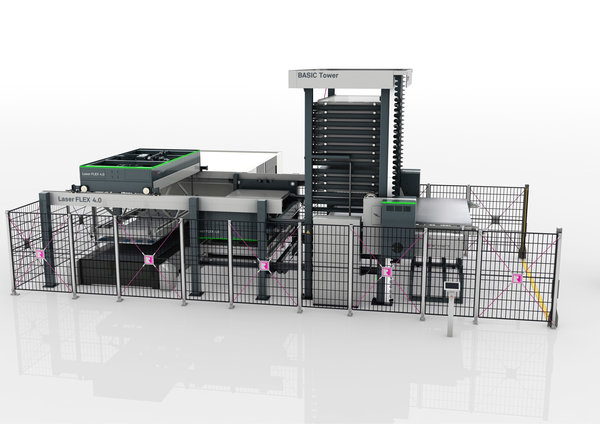

LaserFLEX

The fastest solution for fully automated loading and unloading of laser cutting systems.

All the advantages at a glance:

- Changing times from approximately one minute (at 3015)

- Highly automated manufacture processes

- Decoupling of supply and removal of lasers

- Manufacturer-independent integration of laser systems

- Flexible storage design with tower storage or large systems

- Reduced downtimes for the processing machine

The quickest solution on the market

LaserFLEX is fitted with two automated units - one supplier and one remover. This way Remmert decouples the feeding of the laser systems. After cutting the sheet metal, the fork unit of the new system lifts the processed metal sheet from the laser’s changing table. At the same time, the vacuum unit picks up a new board from the connected storage system. As soon as the remover places the sheet back down or sets it next to the machine, the supplier attaches the new sheet to the laser. The LaserFLEX needs only about one minute to do this - and according to a benchmark study by Remmert, it is the quickest system on the market.

The downtimes of the connected machines are near zero, even lasers with a high processing speed are optimally supported.

Convincing automation technology

- Designed for sheet metal in the formats 3015 and 4020

- Vacuum unit as the supplier

- Fork unit as the remover

- Standard interface for SPS and IT

- Connects to several laser systems in the chain installation

- Integration in the existing storage and production environment

Efficient processes with higher levels of automation

The new robot application for sheet metal enables a higher level of automation in laser-supported manufacture.

In accordance with the various user requirements, LaserFLEX is designed for sheets of metal in the formats 3015 and 4020. Thanks to standard interfaces for SPS and IT, several lasers can be integrated manufacturer-independently at the same time and be supplied in parrallel through an individual robot application with material. The connection to the storage technology is also flexible. For quick access, users can stock the sheet metal in the immediate production environment using single or double tower storage systems. Connection to larger or corresponding Remmert storage systems is always possible.

And what can we do for you?

We’ll be happy to provide you with further assistance.